Announcing "The Polar Mission" - February 2025

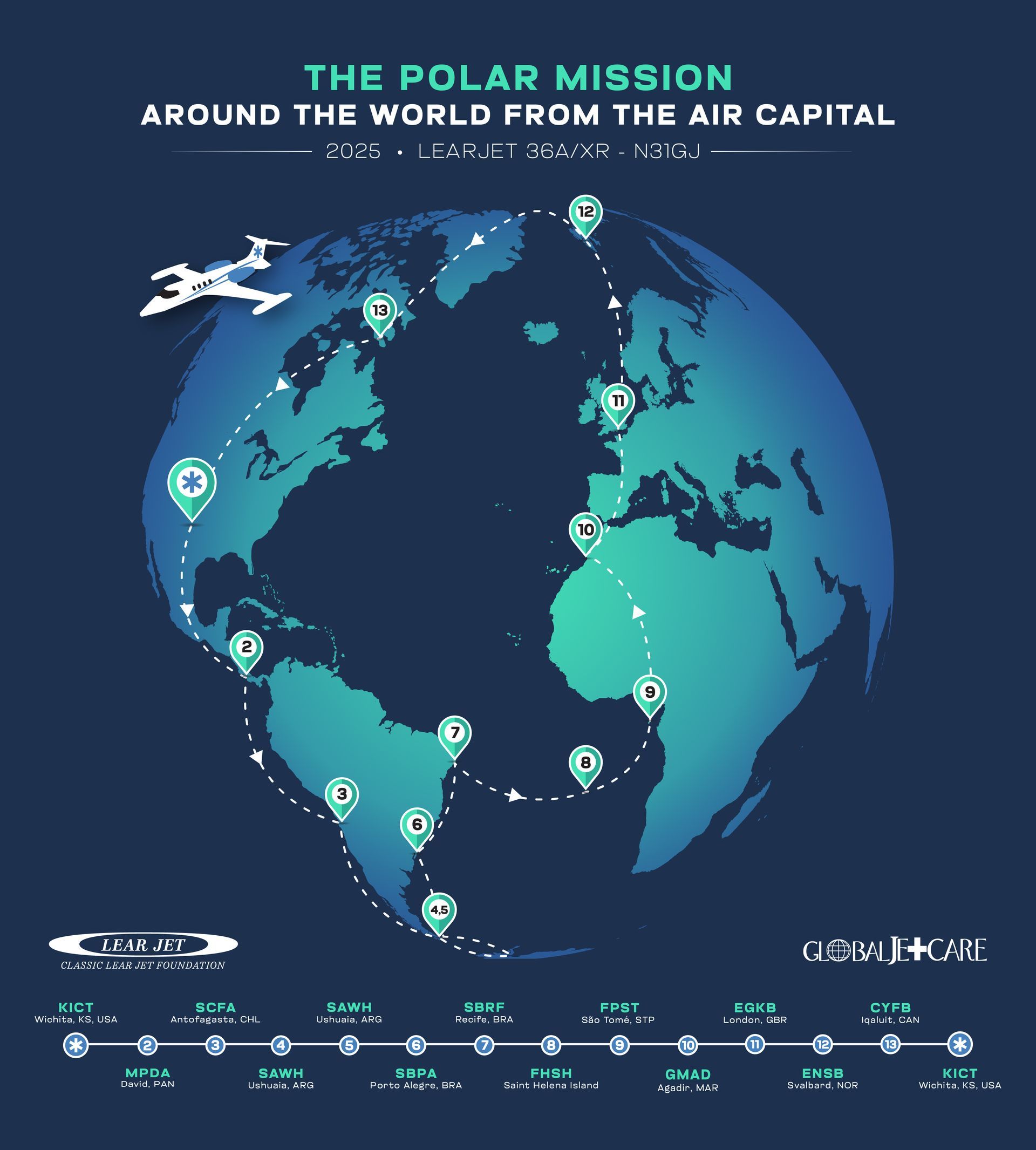

“The Polar Mission” is the name of the record flight attempt by 36A-022 N31GJ and her crew to circumnavigate the globe from north to south by flying over both poles. The “Pole to Pole From the Air Capital” flight is scheduled to depart from the Learjet ramp near building 14 on April 30, 2025. After flying over both poles, is expected to return to the Learjet ramp on May 3, 2025. The scheduled flight path is shown below:

You will note that fuel stops 4 and 5 are at the same airport (SAWH) in Argentina. This is because the plan is to overfly Antarctica and land back at SAWH to refuel before continuing northward. In order to overfly Antarctica the crew had to get special permission from the U.S. State Department! They had to have a special reason for the flight, so during the entire mission they will be doing an official scientific experiment in conjunction with a college. This experiment has to do with measuring the slight variation in the gravitational attraction at the poles versus the equator and along the flight path.

One of the biggest challenges for the flight is the wildly varied weather and temperatures they will encounter. Hot at the equator and extreme cold at the poles! The crew will carry polar survival gear for the ‘just in case’ scenario. Another challenge is access to fuel and, if required, maintenance. While these are plentiful near the normal flight routes, they are pretty scarce near the poles.

We are looking for sponsors for each of the flight legs. Sponsor will have their name or logo displayed on the airplane. Just like “The Century Mission” airplane last year. If you are interested in sponsoring a leg please contact us at info@ClassicLear.org.

In order to celebrate the “The Polar Mission”, we are planning a ‘kickoff’ Hangar Party on April 26th (see details below) and a ‘welcome home’ event when they return. Also, we will set up a website so you can follow the flight as it progresses. (Watch next issue of RECHARGE for the website and preflight updates)

Read the full newsletter by clicking the button below.